Masdar Building, Graphene Engineering Innovation Centre – University of Manchester

Open plans developed around a flexible laboratory module create a research and production environment that is both highly-technical and future-proofed against the inevitably unpredictable evolution of the Centre’s mission.

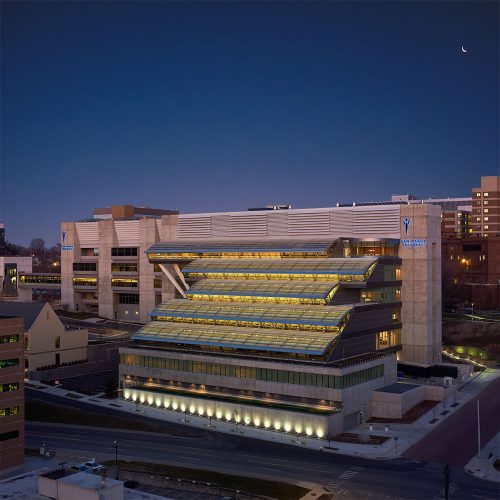

Building on the University of Manchester’s leadership in research and development of graphene and related 2-D materials, the Masdar Building, Graphene Engineering Innovation Centre (GEIC) is a state-of-the-art technical facility critical to exploit and maintain the United Kingdom’s world-leading position in advanced 2-D materials. In the scheme set by the University during the competition stage, the 8,000-square-meter (86,110-square-foot) academic building was presented as a fixed arrangement of laboratories, stacked on three floors. Rafael Viñoly Architects’ design creates two continuous floor plates of modular labs to maximize flexibility of the highly-technical, specialized research space.

The GEIC is the first new building on the redevelopment of the University of Manchester’s North Campus, a prime location in the city centre that could develop into a future “Graphene City.” It will create the world’s leading test-bed for graphene and 2-D material process engineering and scale-up, serving as a complement to the University’s existing National Graphene Institute (NGI)–completed in 2015–where currently 150 scientists and engineers work directly on graphene.

A key driver for the building organization has been to maximize the amount of laboratory space on the lower levels in order to promote interactivity between researchers and cross-disciplinary projects. A modular approach to the organization of the double-height research space offers maximum flexibility. Partitions can be repositioned and equipment of various sizes can be easily deployed to efficiently and effectively meet graphene and 2-D materials development needs.

In the first instance GEIC will focus on pilot production and characterization, together with applications in composites, energy, solution formulations and coatings, electronics, and membranes. These highly-technical laboratory spaces are large volume and open-plan. The building also contains open and closed offices that encourage collaboration while respecting confidentiality requirements and break-out spaces and open workstations to accommodate group research work.

The building’s design responds to its prominent location adjacent to the Mancunian Way urban motorway by creating a glazed street-facing side to show the work being conducted inside. Glazed staircases and projecting elements on the upper office level further connect the building to the city beyond.

In accordance with the University’s sustainability aspirations, the project will be certified BREEAM Excellent. This is being achieved through the careful specification of elements of building fabric, renewable technologies, mechanical systems, and a biodiverse landscape scheme.